Maximizing Efficiency with Reactors Featuring Coil Jackets and Cooling Systems

In industries where precision, high temperatures, and corrosive materials are involved, reactors play a crucial role in ensuring smooth, safe, and efficient operations. One of the most efficient solutions in this regard is the SS321 mixing tank, specifically designed with a reactor featuring coil jackets and an inner paddle mixer with a coil cooling system. This advanced reactor system can maximize production efficiency while maintaining high standards of safety and performance. Let’s dive into how these specialized reactors work, their benefits, and their applications in various industries.

The Power of SS321 Reactors with Coil Jackets

The SS321 mixing tank is designed with stainless steel 321, which is known for its excellent resistance to high-temperature and corrosive environments. This makes it the ideal choice for processing materials like acids, solvents, and other reactive substances. With a focus on high efficiency and robust durability, these reactors are particularly beneficial in industries such as chemical manufacturing, pharmaceuticals, food production, and more.

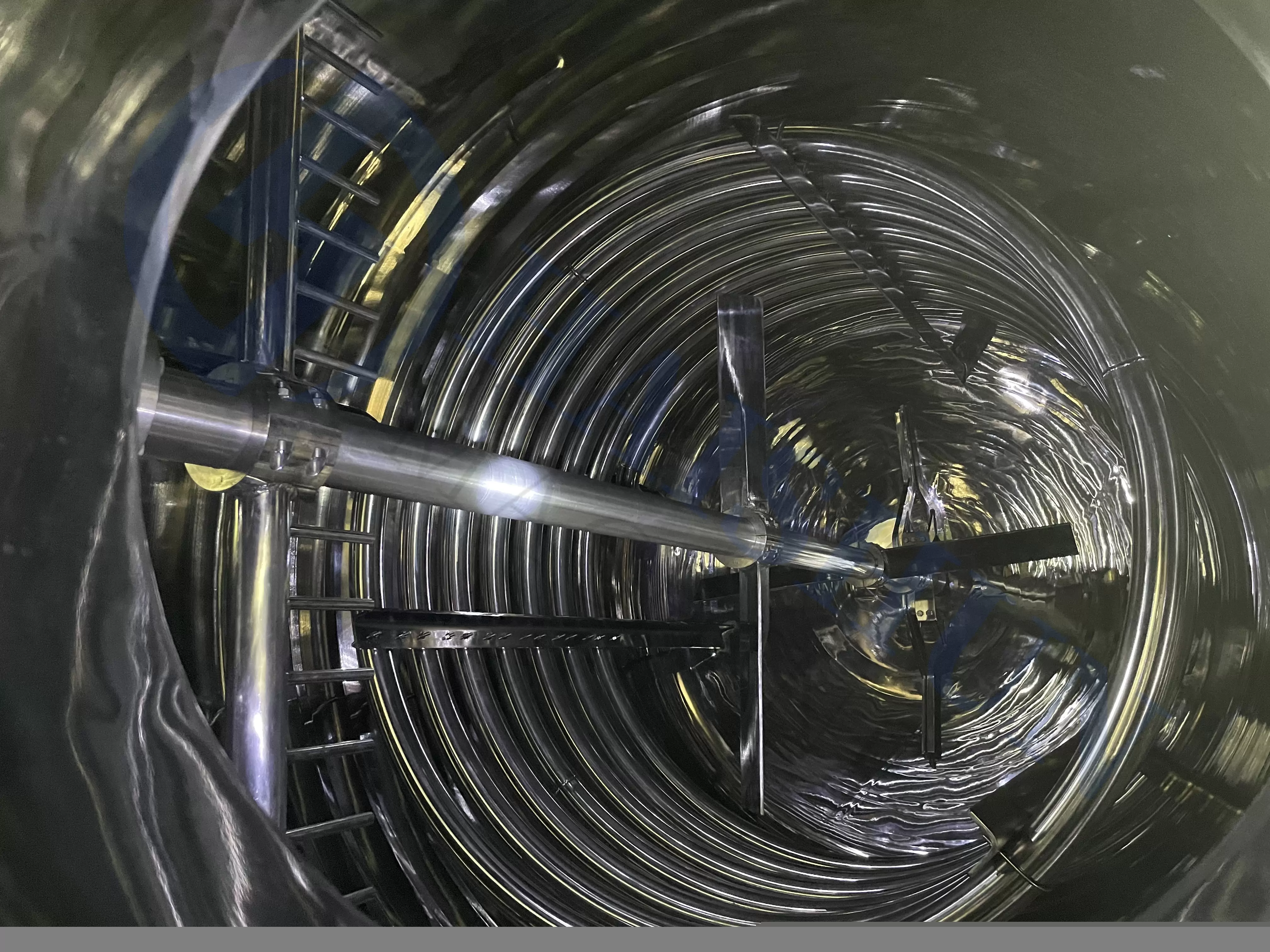

One of the key features of these reactors is the coil jacket, which surrounds the reactor's inner body. This coil jacket serves a vital role in temperature control, which is often a crucial aspect of chemical reactions. By using the coil jacket in conjunction with the internal paddle mixer, the system efficiently maintains the required temperatures, ensuring that the reaction occurs under optimal conditions, which improves both speed and product quality.

The Role of the Paddle Mixer and Coil Cooling System

The inner paddle mixer is designed to meet most mixing needs, particularly in high-speed mixing environments. It provides a powerful stirring action that ensures materials are uniformly mixed without causing shaking or vibrations in the tank. This guarantees that even the most challenging materials are blended evenly and consistently. The 8mm mixing blades are made from the same material as the tank body, ensuring maximum durability and strength.

The coil cooling system is another important feature of the SS321 reactor. The coils are embedded inside the tank, ensuring efficient heat exchange and cooling during the mixing process. This helps maintain the desired temperature and prevents overheating, which can lead to unwanted chemical reactions or damage to the materials. The system is designed with small flanges on the outer wall of the tank, which connect the inner and outer coils, ensuring effective cooling and maintaining process stability.

The Benefits of Coil Jacketed Reactors

Efficient Temperature Control: The coil jacket and internal cooling system allow precise control over the temperature of the materials inside the tank. This is particularly important for sensitive reactions that require stable thermal conditions.

Enhanced Mixing: The paddle mixer ensures that materials are mixed evenly without creating turbulence or excessive agitation. This provides better results in terms of uniformity and consistency, especially for high-viscosity fluids or complex mixtures.

Corrosion Resistance: The SS321 material ensures high resistance to corrosive substances, allowing the reactor to handle aggressive chemicals without compromising the integrity of the tank.

Energy Efficiency: The efficient cooling system reduces the need for external cooling sources, saving on energy costs while maintaining optimal reaction conditions.

Customizable Design: These reactors can be tailored to meet specific production requirements, whether it’s adjusting the size, mixing blade design, or the materials used for the tank and components.

Applications of SS321 Reactors in Various Industries

The versatility of the SS321 reactor with coil jacket and cooling system makes it ideal for use in a wide range of industries. Some common applications include:

Pharmaceutical Industry: Reactors are used for mixing and homogenizing active ingredients, ensuring consistent formulations in drug manufacturing.

Chemical Manufacturing: For mixing chemicals and maintaining precise temperatures for reactions, especially with corrosive substances.

Food and Beverage: In the production of beverages, sauces, and other food products, where uniform mixing and temperature control are essential for product quality.

Paint and Pigment Production: Ensuring uniform consistency in paints, coatings, and dyes, especially with high viscosity and temperature-sensitive materials.

Resin and Polymer Processing: In the manufacture of various polymers and resins, where precise control over reaction time and temperature is necessary.

Why Choose Haishun Machinery?

At Haishun Machinery, we specialize in providing high-quality equipment for various industries, including brewing equipment, pharmaceutical machinery, and food processing systems. Our SS321 mixing tanks with coil jackets and internal paddle mixers are designed to meet the specific needs of our clients, ensuring maximum performance, durability, and efficiency.

With years of experience and a commitment to customer satisfaction, we offer a comprehensive range of solutions, from design and manufacturing to installation and after-sales service. Whether you need a standard reactor or a custom-built system, Haishun Machinery provides flexible and tailored solutions to meet your unique production requirements.

Conclusion

In industries where precise mixing, temperature control, and corrosion resistance are critical, the SS321 mixing tank with a coil jacket and internal paddle mixer stands out as a high-performance solution. Its ability to maintain uniform temperature, coupled with efficient cooling and mixing, makes it indispensable for modern manufacturing processes. With Haishun Machinery’s advanced reactor systems, you can maximize operational efficiency, reduce costs, and ensure the highest quality of your products. Whether you're in pharmaceuticals, chemicals, food, or any other sector, our reactors are designed to meet your specific needs while ensuring long-lasting performance and reliability.

For more information or to customize your reactor system, contact Haishun Machinery today and take the next step toward improving your production processes.